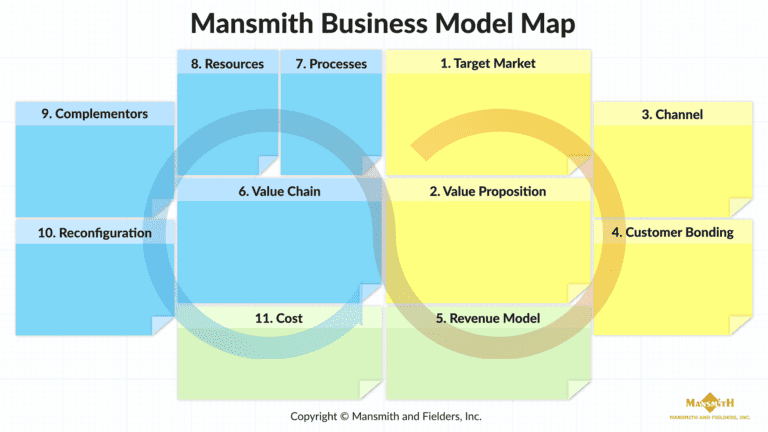

The 11 Building Blocks of a Business Model

A decade ago, I introduced the Business Model Innovation seminar, featuring the “11 Building Blocks of a Business Model.” The Mansmith Business Model Map has two more elements — value chain and reconfiguration — compared to popular business model canvas models.

The value chain, as defined by Harvard’s Michael Porter, is a set of activities a firm operating in a specific industry performs in order to deliver a valuable product for the market. Without understanding the value chain, firms will be missing how the flow of an idea combined with raw materials add value and are translated into output to benefit the customers, as well as the firm. It is the first step in defining a business’ operating model, and the step before identifying key processes and key resources in the business model map.

Reconfiguration is about innovation. It is about what to start and stop doing in your industry, in order to be different in a different way. Without reconfiguration or innovation, a firm can still have a business model but may not be as innovative compared to its competitors.

It is my belief that in any business design, it is a must to define these two elements, along with these other elements below:

The Offering Model

Target market

Value proposition

Channel

Customer bonding strategy

Revenue model

The Operating Model

Value chain

Key processes

Key resources

Complementors

Reconfiguration

Cost

Revenue (no. 5) and cost (no. 11) also comprise the financial model of a business model.

Let’s look at two examples to emphasize value chains and reconfiguration.

Value chain

Steel Asia is the flagship steel company in the Philippines. It manufactures nearly one out of every two steel bars in all construction projects, and supplies about 80% of rebars (or reinforcing bars) for local infrastructure projects. Rebars are the lowest tier of steel manufacturing and are typically a commodity in the different major regions in the Philippines.

Steel Asia innovated its value chain when it built smaller rebar mills across different regions in the Philippines. The mills cut down on freight costs, and savings were passed on to customers.

Steel Asia also permits customers to pick up rebars from the mills, further cutting down the cost to transport rebars from mills to construction sites.

The regional rebar mills and investment in technology made it possible for Steel Asia to provide one of the most competitive offers to customers, and maintain its spot among the best steel companies in the world.

Reconfiguration

Bounty Fresh is one of two national dressed chicken manufacturers in the Philippines. It’s profit rose by 63% in the first half of 2020, when they launched, among others, over 100 rolling stores to sell both dressed and cooked chicken during the COVID-19 pandemic.

Before the pandemic, Bounty Fresh started a chain of rotisserie chicken stalls (Chooks to Go), followed by charcoal-grilled chicken stalls (Uling Roaster) as a way to secure their future against declining import tariffs brought about by globalization. Over 1,700 of their stores surpassed the combined number of stores of competition Andok’s, Baliwag, Sr Pedro, and more, making them the dominant market leader of the retail cooked chicken industry without having to offer sauce in Chooks-to-Go products (a staple in other outlets) and offering consumers lock-in flavors.

Business Model During the Pandemic

The above two cases showed:

How value chain design helped firms identify opportunities that can create better value for customers (smaller steel mills in key cities outside the main plant for Steel Asia, chain of chicken outlets for Bounty Fresh) as well as counter threats of competition or substitutes. How reconfiguration or innovation makes it harder for competition to catch up, and creates more value not just for a firm’s consumers but to the firm as well by way of competitive advantage.

Responses